BERTHING SOLUTION

NJ Maritech offers the widest range of marine fenders to suit almost all types of berthing applications in various climatic and site conditions. Our every fender system is custom-designed to match the berth structure, tides, approach conditions and environmental extremes. We trust you find our product catalog informative. Should there be any information you seek, we would be honored to guide and work along with you on your requirement.

CONE FENDER (NCN)

.png)

This type of fender can be considered as the latest in state-of-art molded fender products. Its refined geometry and conical shape result in a number of outstanding performance characteristics.

- Higher Energy Absorption to Reaction Force Ratio (E/R).

- Outstanding energy absorption per weight of fender.

- High shear stability which allows the fender to carry even larger panel weights without using chains.

- Very good inherent resistance against shear forces due to its geometry and self-centering characteristics.

- No reduction of energy absorption up to 10° compression angle.

- Internal overload stopper as OPTIONAL.

- Availability in heights between 300 and 2000 mm..

CELL FENDER (NCL)

.png)

This fender has a hollow cylindrical body with fully rubber-embedded mounting flanges and is designed to deflect in an axial direction. Cell fenders are very robust and have been used for decades in many ports around the world.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- Integrated and fully-embedded fender flanges make assembly & installation simple.

- Good shear force resistance due to the large diameter of the fender flanges.

- Large fender foot print with good force distribution could lead to relative light panel construction.

- Available in heights between 400 to 3000 mm, each in various different hardness grades for the most precise fender selection.

ELEMENT FENDER (NEL)

.png)

Element fenders are fully molded rubber legs with embeded mounting plates. In principal they are based on V-fenders but separated legs increases fender layout flexibility when installed behind steel panels or where mounting space is restricted.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- High energy absorption per weight of rubber.

- Modular and compact design with small footprint.

- Vertically and horizontally mounted elements may be combined in one system.

- The NEL fender element is available in heights between 250 to 2000 mm, in standard lengths ranging from 500 to 2000 mm each in various hardness grades for the most precise fender selection.

TR FENDER (NTR)

NTR Fenders are an innovation in modern element fender. These fenders having fender fitting flanges at both sides which offer more sturdiness as compared to element type of fenders. In principle they are based on V-fenders but separated legs increase fender layout flexibility when installed behind steel panels or where mounting space is restricted.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- High energy absorption per weight of rubber.

- Vertically and horizontally mounted NTR fenders may be combined in one system.

- The NTR fender element is available in heights between 400 to 2000 mm, in standard lengths ranging from 500 to 2000 mm each in various hardness grades for the most precise fender selection.

ARCH FENDER (NAH)

.png)

Arch fenders are simple and rugged, providing reliable and trouble-free service for a wide variety of berths even under the most severe conditions. The NAH fender is a traditional rubber faced unit with considerably greater energy absorption.

- Simple one piece design.

- Excellent shear performance.

- Can be arrange vertically or Horizontally.

- Good energy absorption and low reaction force.

- The NAH fender is available in heights between 150 to 1000 mm, in standard lengths ranging from 1000 to 3500 mm each in various hardness grades for the most precise fender selection.

ARCH FENDER WITH UHMW (NAHP)

.png)

Arch fenders are simple and rugged, providing reliable and trouble-free service for a wide variety of berths even under the most severe conditions. The NAHP fender can be fitted with either UHMW-PE or connected to a steel panel.

- Simple one piece design.

- Excellent shear performance.

- Can be arrange vertically or Horizontally.

- Good energy absorption and low reaction force.

- The NAH fender is available in heights between 150 to 1000 mm, in standard lengths ranging from 1000 to 3500 mm each in various hardness grades for the most precise fender selection.

CORNER ARCH FENDER (NCA)

.png)

NCA series Corner Arch Fenders are an improved version of other solid fenders like Arch & Wheel fender. The NCA fender can be also fitted with UHMW-PE pads.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- Excellent shear performance.

- High load carrying capacity.

- The NCA fender is available in heights between 150mm, 200mm & 300 mm in respective lengths of 1000mm, 725mm, 625mm.

FOAM FILLED FENDER (NFF)

.png)

NFF series Foam Filled fenders are extremely robust and do not suffer loss of performance even if damaged. Foam filled floating fenders are used as alternative solution to both fixed fenders and pneumatic fenders. They are widely used in Heavy duty ship-to-ship lightering operations & all Navy vessel berths due to low hull pressure.

- Optional chain/tyre net for heavy duty applications.

- The NFF fender is available in Diameter from 300mm to 4500 mm in standard lengths of maximum 12000mm.

PNEUMATIC FENDER (NPF)

.png)

NPF series Pneumatic fenders can easily be deflated which allows simple and cost efficient relocation and recommissioning in other locations. Pneumatic fenders are a proven alternative to fixed fenders and are preferably used in ports with extreme tidal variations, for ship-to-ship lightering operations & for all Navy vessels due to low hull pressure and the advantage of a proportional increase of reaction force and energy absorption.

- Optional chain/tyre net for heavy duty applications.

- Two different inside pressure levels to cover a wide performance range.

- Special hydro-pneumatic version for submarines.

- The NFF fender is available in Diameter from 300mm to 4500 mm in standard lengths of maximum 12000mm.

CYLINDRICAL FENDER (NCY)

.png)

NCY series Cylindrical Fenders have defined performance. Installation is simply achieved by using chains, bars, ropes or specially designed ladder brackets. Their proportional increase of reaction force and energy absorption all the way to the rated deflection is an advantage resulting in softer erthing.

- Very robust and simple fender type.

- Easy to install, allowing multiple usage at different berths.

- Special dimensions and features such as pre-bending or jointing can be requested.

- The NCY fender is available in Outside diameter up to 2700 mm & standard lengths ranging from 1000 to 3000 mm.

M-TYPE FENDER (NMF)

.png)

NMF Fender is improved version of the Arch fender. These fenders are having more deflection and better Energy/Reaction ratio. Because of wide fender face, the Hull pressure is also relatively low as compared to Arch Fenders.

- Easy to install.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- Excellent shear performance.

- The NMF fender is available in heights between 250 to 1000 mm, in standard lengths of maximum 3500 mm.

NCV FENDER

These fenders are having more deflection and better Energy/Reaction ratio. NCV & NBP Fenders are suitable for a wide variety of uses on the berth and on a wharf.

- Easy to install.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- Excellent shear performance.

NBP FENDER

These fenders are having more deflection and better Energy/Reaction ratio. NCV & NBP Fenders are suitable for a wide variety of uses on the berth and on a wharf.

- Easy to install.

- Good Energy Absorption to Reaction Force Ratio (E/R).

- Excellent shear performance.

BOAT OR TUG FENDER (NTF)

.png)

Tug or Boat Fenders are more harder & stable under more extreme conditions than any other fender type. A complete “ready to install” fender kit including tapered ends, connecting plugs, end plugs, drill holes as well as numbered stern and bow fender sets are available.

- Best performance in dynamic load effect.

- Widely used on ship’s Hull & other structural applications.

- The NTF fender is available in Diameter from 200mm to 1200mm.

ROLLER & WHEEL FENDER (NRF)

.png)

Roller or Wheel fenders help vessels maneuver into berths & narrow channels. They are usually installed to guide ships in restricted spaces like walls of dry docks, on corners & lock entrance.

- Suitable for all kinds of harbor.

- Provide a defined energy absorption capacity in addition to guiding the vessel.

- Used in single or multiple stacks.

- Selection of the appropriate type, size and casing is dependent on the specific project requirements.

W - FENDER (NWF)

.png)

NWF fenders offer an excellent alternative to square fenders. A complete “ready to install” fender kit including connecting plugs, end plugs, drill holes as well as numbered stern and bow fender sets are available.

- Best performance in dynamic load effect.

- Widely used for Bow & AFT fendering.

- These fenders can also be installed on curved structures and round corners.

PE-SLIDING FENDER (NPS)

.png)

NPS Sliding fender made of Polyethylene is used in many applications in the marine environment such as on marine structures, pontoons and ships front face for fender panels. UHMW -PE (1000 FQ) mainly used as low friction and rubbing pad for fender panels. HD-PE sliding fenders, predominantly used to replace wooden beams/Timbers.

- Widely used for low shear force application.

- Easy to install.

- Provides a simple & extremely durable fendering solution.

TIMBER FENDER (NTF)

.png)

The most common wood used in Marine fendering is GREENHEART (Ocotea rodiael) is one of the strongest commercially available Timbers in the market.

- Ideally suited for salt and fresh water application.

- Easy to install.

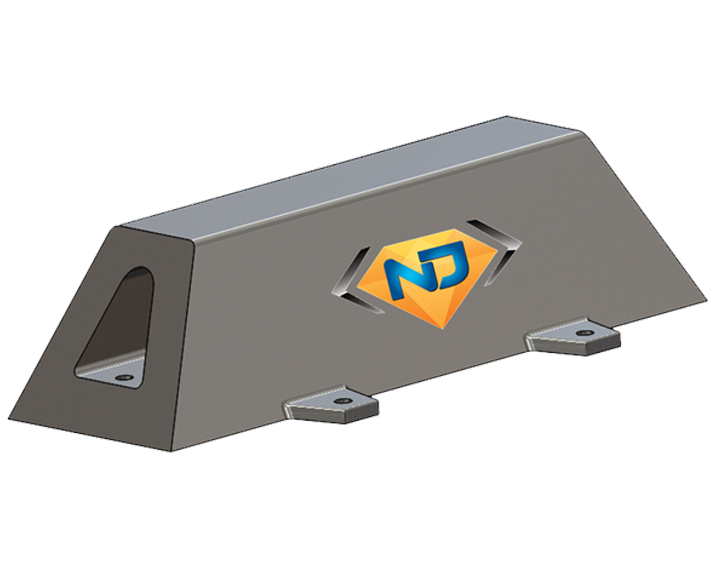

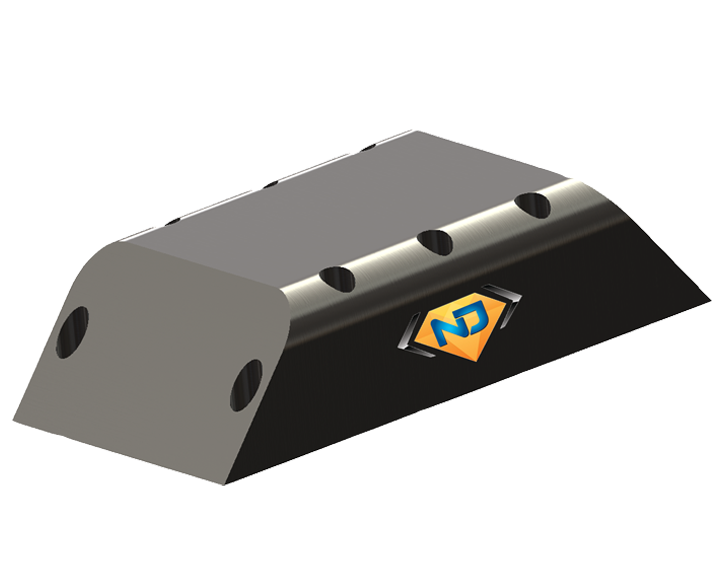

CAR STOPPER (NCS)

.png)

NCS series Car Stopper is made from high density Polyethylene (HDPE) which is excellent water-resistance, abrasion resistance & impact-resistance.

- Easy to install.

- Ideally suited for salt and fresh water application.

NDO Fender

Extrude type fenders are commonly used on floating pontoons and on inland waterways for lock protection.

- Easy to install.

- Good energy absorption ratio.

- Used for Light/medium duty applications for small vessels.

- Provides a simple & extremely durable fendering solution.

NDD Fender

Extrude type fenders are commonly used on floating pontoons and on inland waterways for lock protection.

- Easy to install.

- Good energy absorption ratio.

- Used for Light/medium duty applications for small vessels.

- Provides a simple & extremely durable fendering solution.

NSD Fender

Extrude type fenders are commonly used on floating pontoons and on inland waterways for lock protection.

- Easy to install.

- Good energy absorption ratio.

- Used for Light/medium duty applications for small vessels.

- Provides a simple & extremely durable fendering solution.

NSO Fender

Extrude type fenders are commonly used on floating pontoons and on inland waterways for lock protection.

- Easy to install.

- Good energy absorption ratio.

- Used for Light/medium duty applications for small vessels.

- Provides a simple & extremely durable fendering solution.

NKH - Key Hole Fender

.png)

Extrude type fenders are commonly used on floating pontoons and on inland waterways for lock protection.

- Easy to install.

- Good energy absorption ratio.

- Used for Light/medium duty applications for small vessels.

- Provides a simple & extremely durable fendering solution.